Blog

Top 10 Food Packing Machines for Efficient Packaging Solutions

In the fast-paced food industry, efficiency and reliability are paramount, particularly when it comes to packaging. A food packing machine serves as a vital component in the production process, ensuring that products are sealed, stored, and preserved to maintain their quality and freshness. With an increasing demand for convenience and safety among consumers, the right packing solution can significantly enhance the operational capabilities of food businesses, from small startups to large enterprises.

This article explores the top 10 food packing machines that are revolutionizing the industry. These machines not only streamline packaging processes but also improve productivity by minimizing labor costs and reducing the likelihood of human error. As technology advances, the features embedded in modern food packing machines have become more sophisticated, offering innovations that cater to various food types and packaging requirements. From vacuum sealing to automatic bagging, the options are diverse, allowing manufacturers to select equipment that best meets their specific needs.

By examining the latest advancements and popular choices in food packing machines, we provide insights into how these machines can transform your packaging operations, ensuring that your products not only meet regulatory standards but also appeal to the ever-evolving preferences of consumers. Join us as we delve into the top solutions that promise efficient packaging and bolster your business success in the competitive food market.

Top Food Packing Machines Overview

In the fast-paced world of food packaging, efficiency stands at the forefront of operational success. As the sector continues to evolve, the demand for innovative food packing machines has surged, driven by the need for automation and improved productivity. According to a recent market analysis report, the global food packaging machinery market is projected to reach approximately $50 billion by 2025, reflecting a compound annual growth rate (CAGR) of around 4.5%. This growth is largely attributed to the increasing consumer preference for ready-to-eat and convenience foods, necessitating more sophisticated packaging solutions.

When selecting food packing machines, it is crucial to consider the specific requirements of your production line. Each type of machine—from vertical form-fill-seal (VFFS) to horizontal flow wrappers—offers unique benefits tailored to various food products. For instance, VFFS machines are particularly advantageous for high-speed operations and can accommodate a wide range of packaging materials. As per industry insights, automating food packaging processes can enhance efficiency by up to 30%, leading to significant cost savings in labor and material.

Tips: When investing in food packing machinery, assess your production needs and future scalability. Collaborate with equipment manufacturers to ensure compatibility with your current setup and explore options for custom solutions. Moreover, prioritize machines that offer versatility to handle diverse product types, as this can greatly improve your competitive edge in the market.

Top 10 Food Packing Machines for Efficient Packaging Solutions

| Machine Model | Type | Packaging Speed (units/min) | Power Consumption (kW) | Dimensions (mm) | Weight (kg) |

|---|---|---|---|---|---|

| Model A | Vertical Form Fill Seal | 60 | 2.5 | 1500 x 800 x 1800 | 350 |

| Model B | Horizontal Flow Wrapper | 80 | 3.0 | 2000 x 1000 x 1500 | 450 |

| Model C | Cup Filler | 100 | 1.8 | 1200 x 800 x 1800 | 250 |

| Model D | Pouch Packaging Machine | 50 | 2.2 | 1600 x 900 x 1700 | 300 |

| Model E | Shrink Wrapper | 70 | 2.7 | 1900 x 1100 x 1500 | 400 |

Key Features to Consider in Food Packing Machines

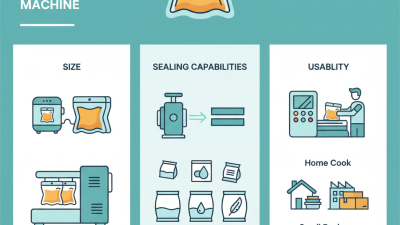

When selecting a food packing machine, several key features should be considered to ensure efficient packaging solutions. Firstly, the type of packaging required should guide machine selection. Machines designed for specific formats, such as pouches, trays, or vacuum sealing, will perform better for certain products. Additionally, the size and volume of the food items play a crucial role; a packing machine should be capable of handling the intended production rate without compromising on quality or safety.

Another critical aspect is the ease of use and maintenance. Machines equipped with user-friendly interfaces can significantly reduce the training time for operators and minimize errors during the packing process. Moreover, ease of cleaning and maintenance contributes to operational efficiency and hygiene, particularly in food production environments. Advanced features, such as automatic calibration and self-diagnostics, can enhance reliability and reduce downtime, ensuring that production schedules are met consistently.

Lastly, versatility and adaptability are essential features for modern food packing machines. The ability to switch packaging formats quickly can be a significant advantage for businesses that deal with a variety of products. Furthermore, energy efficiency and sustainability are becoming increasingly important considerations, as they not only lower operational costs but also align with environmental goals. By focusing on these key features, businesses can choose the right food packing machine that meets their packaging needs effectively.

Types of Food Packing Machines Available

When it comes to food packaging, selecting the right type of packing machine is crucial for ensuring both efficiency and product quality. Various types of food packing machines are available, each designed to cater to specific packaging needs. One popular category is vertical form-fill-seal machines, which are ideal for products like granules, powders, and liquids.

These machines use a vertical pouching system that creates bags from a roll of film, fills them with product, and seals them up, making them highly efficient for fast-paced production environments.

Another essential type is the horizontal flow wrapper, commonly used for packaging snacks, baked goods, and ready-to-eat meals. These machines operate by placing the food item on a film and folding it around, ensuring the product is well-protected and visually appealing. Additionally, tray sealing machines are popular in the packaging of fresh produce and prepared meals. They use a method of sealing a film over a pre-formed tray, providing an airtight seal that prolongs shelf life while showcasing the product beautifully.

For liquid packaging, pouch filling machines are versatile options that cater to items like sauces and beverages. These machines are designed for precision and hygiene, ensuring that the liquid contents are securely sealed without spills. In summary, the landscape of food packing machines is diverse, with solutions tailored to different product types and packaging requirements, ultimately enhancing operational efficiency and maintaining product integrity.

Benefits of Efficient Food Packing Solutions

Efficient food packing solutions play a crucial role in the food industry, enhancing not only the preservation of products but also improving overall operational productivity. One of the primary benefits of utilizing advanced packing machinery is the significant reduction in labor costs. These machines automate repetitive tasks, allowing employees to focus on more strategic roles in production and quality control. This shift not only increases output but also minimizes the risk of human error, ensuring that products are packed consistently and accurately.

Moreover, efficient food packing solutions contribute to extended shelf life and enhanced product safety. By utilizing innovative packaging technologies, businesses can better protect food items from contamination, spoilage, and damage during transportation. This protection is vital for maintaining quality and freshness, which ultimately leads to higher customer satisfaction. Additionally, well-designed packaging can facilitate easier distribution and storage, optimizing space usage and reducing waste. In a competitive market, these advantages are essential for maintaining a strong presence and ensuring long-term sustainability.

Future Trends in Food Packing Technology

The future of food packing technology is poised to undergo significant transformations driven by advancements in automation, sustainability, and smart technology. As consumer preferences evolve, there is an increasing demand for packaging solutions that not only enhance product shelf life but also cater to environmentally conscious practices. Innovations in biodegradable and recyclable materials are becoming essential, pushing manufacturers to adopt eco-friendly options that reduce waste and environmental impact. These materials are likely to gain traction, aligning with the growing trend of sustainability within the food industry.

Moreover, the integration of smart technology into food packing machines is set to revolutionize the efficiency and accuracy of packaging processes. The use of artificial intelligence and machine learning enables real-time monitoring and predictive maintenance, reducing downtime and minimizing waste. Automated systems can adjust packaging processes based on various factors such as temperature and humidity, ensuring optimal conditions for food preservation. Additionally, the rise of IoT (Internet of Things) applications allows for seamless connectivity between machines and supply chains, facilitating greater transparency and traceability in food distribution. As these technologies continue to evolve, they hold the potential to redefine operational standards and enhance the overall quality of food packaging solutions.

Top 10 Food Packing Machines - Efficiency Ratings

Related Posts

-

2025 How to Choose the Best Chamber Vacuum Sealer for Your Needs

-

Top 10 Vacuum Packaging Machines for Home Use in 2023

-

Top 10 Packing Machines for Efficient Packaging in 2023

-

How to Choose the Best Vacuum Packaging Machine for Your Needs

-

Top 10 Benefits of Using Vacuum Seal Bags for Food Storage and Preservation

-

Why You Need a Meat Chamber Vacuum Sealer for Perfect Food Preservation