Blog

2026 Best Packing Machine Options for Efficient Packaging Solutions?

In the fast-paced world of packaging, selecting the right packing machine is crucial for businesses. According to a report by Fortune Business Insights, the global packaging machinery market is projected to reach $50 billion by 2026, highlighting the increasing demand for efficient solutions. The right machine can improve speed and reduce waste, yet many companies struggle with choosing the optimal equipment.

Efficiency in packaging is not merely about speed. The design and technology behind packing machines greatly influence the quality of packaging. Packaged goods need to retain their integrity from production to shelf, and a poorly chosen machine can lead to product damage. Reports indicate that nearly 30% of packaging failures stem from inadequate machinery and processes. Companies must reflect on their current practices and seek machines that align with their specific needs.

Moreover, innovations like automated packing systems are reshaping the industry. They offer increased flexibility and scalability, crucial in today's fluctuating markets. However, relying on these advanced machines without proper training can lead to unexpected challenges. The goal is to enhance productivity while maintaining quality—a delicate balance that requires thoughtful consideration of various packing machine options available in 2026.

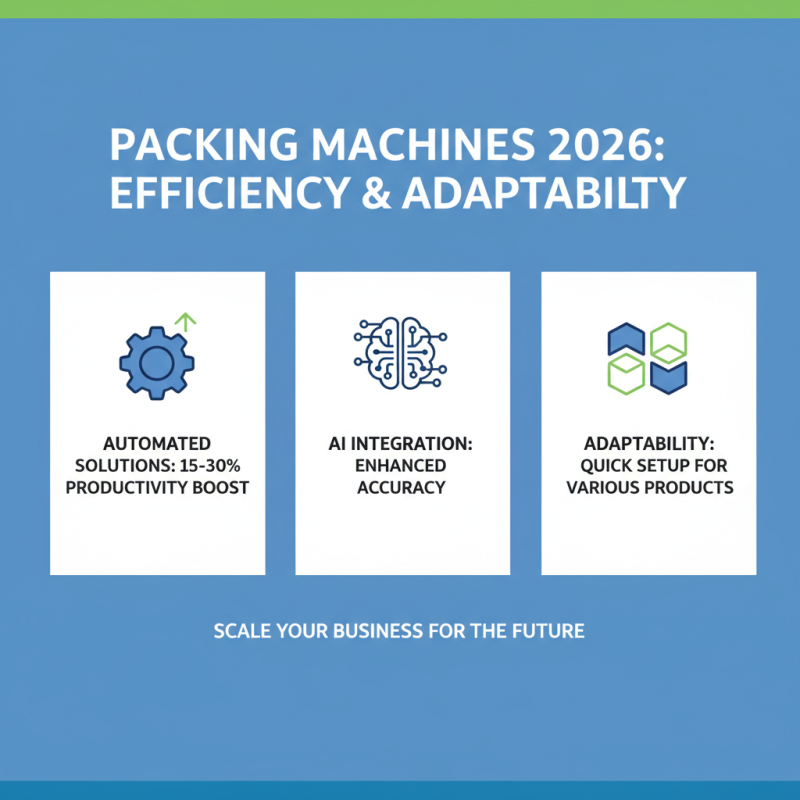

Top Features to Consider in Packing Machines for 2026

When selecting packing machines for 2026, it's crucial to consider efficiency and adaptability. Industry data indicates that automated packing solutions boost productivity by 15-30%. This is vital for businesses looking to scale operations. Machines that incorporate artificial intelligence can significantly enhance accuracy. They can adjust to different product sizes and types without lengthy setup times.

Moreover, look for machines with real-time monitoring. Data suggests that 70% of manufacturers benefit from live analytics. This feature can reduce downtime and improve output quality. Energy efficiency also matters. Reports show that eco-friendly packing solutions are gaining traction. These machines not only cut costs but also align with sustainability goals.

Another key feature is ease of use. Simple interfaces can reduce training time. However, some machines are still complex. A balance between technology and user-friendliness is often missing. As more companies embrace automation, the challenge will be to find solutions that do not complicate the workflow. In a rapidly evolving market, packing machines must not only meet current needs but be scalable for the future.

Types of Packing Machines: Options for Various Industries

Packing machines are crucial in various industries, enhancing efficiency and accuracy. The types of packing machines available cater to specific needs. In the food industry, for instance, flow wrappers are popular for their speed. These machines can produce up to 300 packages per minute, ensuring high output.

In pharmaceuticals, blister packaging machines are essential. They protect products from moisture and contamination. The global market for blister packaging is projected to grow by 6.1% from 2022 to 2030. This growth indicates the need for reliable packaging solutions in sensitive sectors.

**Tip:** Assess your production capacity before selecting a machine. Choose one that matches your output demands.

While automatic machines offer speed, they can sometimes lack flexibility. This inflexibility can be a hurdle in adapting to new product lines. Manual packing might be slower, but it allows for adjustments and attention to detail. Balancing efficiency with adaptability is key.

**Tip:** Consider a hybrid approach, using both automated and manual methods.

Investing in the right packing equipment can lead to significant savings and improved quality. Analyze your specific requirements carefully before making a decision. A well-chosen machine can enhance your packaging process and streamline operations.

Efficiency Metrics: Evaluating Packing Machine Performance

In evaluating packing machine performance, efficiency metrics play a critical role. Key performance indicators (KPIs) like throughput, downtime, and waste rates significantly affect operational productivity. According to industry reports, an efficient packing machine can boost throughput by 25% compared to older models. However, this metric can often be misleading without context. A high throughput could lead to increased waste if not paired with precise filling technologies.

Another crucial metric is downtime. Research indicates that unplanned downtime can cost manufacturers up to $250,000 per hour. Identifying the cause of downtime is vital for improvement. Some machines may require frequent adjustments, leading to inefficiencies. This raises questions about long-term reliability and overall return on investment.

Waste rates are also pivotal in assessing efficiency. The latest studies show that reducing waste by just 10% can enhance profit margins by up to 3%. However, many companies overlook this aspect. They may focus solely on speed. Balancing speed and precision in packing is essential. Efficient machines should provide reliable packing without excessive material waste.

2026 Best Packing Machine Options for Efficient Packaging Solutions

This chart evaluates the performance of various packing machines based on efficiency metrics such as speed (units per hour), accuracy (%), and energy consumption (kWh). The data shown illustrates the relative strengths of each machine category in these key performance areas.

Integrated Technology in Modern Packing Machines

Modern packing machines are at the forefront of technological integration. These machines now utilize advanced sensors and robotics. This not only speeds up packaging processes but also enhances accuracy. For instance, automatic weight sensors ensure that every package is filled precisely. Reducing waste is a critical concern in the industry. Integrated technology addresses this efficiently.

Moreover, user-friendly interfaces are becoming standard. Operators can quickly adjust settings and monitor operations. However, the learning curve can be steep for some users. Ongoing training is necessary to maximize machine capabilities.

This highlights an area for improvement. As technology evolves, keeping staff updated is crucial for success. The integration of real-time data analytics can significantly enhance efficiency. Yet, relying solely on technology may overlook human insights. Balancing automation with human intuition may yield the best results.

Cost vs. Value: Budgeting for Packing Machine Investments

When investing in packing machines, careful budgeting is crucial. Companies often face the dilemma of choosing between low cost and high value. A cheaper machine might seem appealing at first. However, hidden costs can arise. Frequent breakdowns and maintenance can make it expensive in the long run. Assessing the total cost of ownership is essential for making a smart choice.

Consider the features that align with your production needs. A machine with advanced technology may save time and labor costs. Look for machines that offer flexibility, allowing adjustments for different packaging types. This adaptability can lead to better resource utilization. Investing in more efficient machines often means higher upfront costs. But these machines can significantly reduce operational delays.

Understand that every investment has trade-offs. A more reliable machine reduces frustrations and downtime. Yet, some may stretch the budget. It’s vital to weigh immediate costs against future benefits. Research extensively before making a decision. Balancing cost and value leads to successful long-term outcomes. Each choice carries consequences, and reflection can guide better future investments.

Related Posts

-

Top 10 Food Packing Machines for Efficient Packaging Solutions

-

Top 10 Benefits of Using an Automatic Packing Machine?

-

2026 How to Choose the Best Vacuum Sealer for Your Needs?

-

Top Benefits of Using a Chamber Vacuum Sealer for Food Preservation

-

What is the best vacuum sealer for home use?

-

What Are the Best Tips for Using a Vacuum Packer?